Aire met Hugo Delavelle. This cabinetmaker creates wooden furniture. He works in a circular economy. In this interview, you'll discover how he develops designer furniture using local materials and an environmentally friendly approach. We're talking about cabinetmaking and the circular economy.

Can you briefly introduce yourself and your cabinetmaking and circular economy workshop?

My name is Hugo Delavelle, I'm 37 years old. I'm a cabinetmaker and designer by training. I started my business in 2009: Atelier Hugo Delavelle. I started as a self-employed entrepreneur, working alone in my parents' garage. After two years, I hired my first employee and changed my status to SARL. Today, there are ten of us. We opened a new cabinetmaking and circular economy workshop last year.

How did you get into the world of cabinetmaking and the circular economy?

Initially, I did a vocational certificate in cabinetmaking. For 10 years, I worked in various companies: cabinetmaking, furniture restoration, kitchen design, fittings, contemporary cabinetmaking, traditional cabinetmaking, but also artisanal and industrial cabinetmaking.

The cabinetmakers I worked in were making less and less furniture, or even no furniture at all. I looked for a lever to overcome this. I identified design as a potential source. So I went to Germany in 2007. I studied artisanal design there for two years. Then in 2009 I returned to France and created my cabinetmaking and circular economy company.

Can you explain your combination of traditional cabinetmaking know-how and the circular economy?

Artisan design is not very present in France. In Germany, there are about twenty schools that train artisans in design. I was in one of them in Aachen, at the Gut Rosenberg Academy. In France, there is the Boule school, which is similar. We have a much more artistic approach in France. There is a strong artistic approach linked to the materials and the craftsman's know-how. But there is no design approach that is more functionalist, with concerns about economics, ergonomics, and industrial applications. Artisan design is therefore the skills of the industrial designer that we have in France combined with know-how.

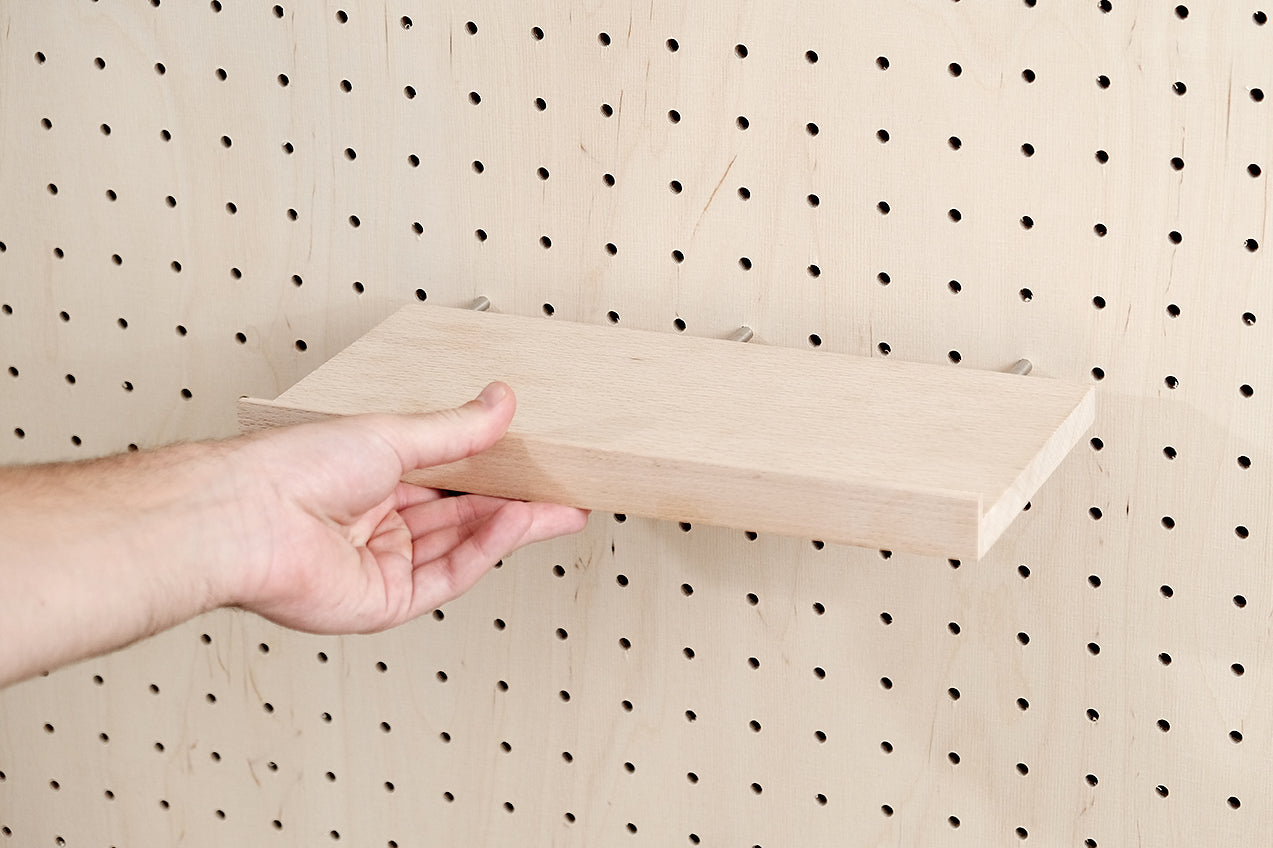

I do everything: from furniture design to manufacturing. Despite the fact that the company is growing, I haven't changed the creative process. We emphasize craftsmanship and not just form. This gives a field of creative expression that is a little different from the industrial designer per se. He often creates form for form's sake, without necessarily knowing the ins and outs of the material that will then be worked.

Precisely, can you develop a little more your creative process and your way of working?

Today, all the pieces we market are pieces that I designed. We don't really have a structured creative process like there can be in industrial design, where there's really marketing that makes a brief beforehand. It's a bit long and not necessarily very attractive. The designer will then digest all this marketing data to create something that fits. I have a little more freedom.

If one morning I want to design a chair, I make a chair, without worrying about all the marketing stuff. Even if we think about it, of course. If I create a bar stool, I will create a high table to go and approach restaurants, for example. However, I have a great degree of freedom.

In my case, it's often the set of constraints I set for myself that are the foundation of the creative process. For example, the material if I have wood scraps of a given size. This can also come from the desire to have a reduced environmental impact on the product.

Material, environmental impact, and functionality are constraints that I try to address as favorably as possible. The intrinsic aesthetics of the product are often a result of constraints related to ergonomics, materials, material savings, and environmental impact.

View this post on Instagram

Do you have an eco-responsible approach?

This is really the basis of our entire approach. The CSR aspect, minimizing the impact of the product, the process, and the company in the broadest sense, is what is at the heart of the approach.

How do you define your job, what qualities are required?

I became a manager somewhat by force of circumstance. We have about ten employees, with much greater financial stakes. We have a turnover of around one million euros. We have just acquired a building that is more industrial, with 4,000 m² of construction on a large platform of 25,000 m².

Now, I wear more of a manager's hat than a cabinetmaker or designer's. The design and cabinetmaking time I produce per week is less at the moment. There are a lot of management, administrative, and also marketing tasks to do. In my case, you need to be adaptable and willing to take on challenges. You have to learn a new skill almost every day.

Do you think your profession will have to reinvent itself? Especially with the pandemic we're going through?

Not particularly, no. I don't think it's going to change much in the long term. We work with local wood, with local stakeholders, and sawyers who are true partners. When I started, we sawed our own wood. We plan to create our own sawmill so we can buy wood from the local forest and do the initial processing.

We will work in a circular economy and locally. This circular economy approach and working in an artisanal, rather than industrial, way has meant that we are less impacted than people who produce furniture with components from all over the world.

What is the “Living Heritage Company” label that you received?

This is a label awarded by the state and rewards companies with "exceptional expertise." The goal is to promote them in France and abroad. It is supported by the National Institute of Arts and Crafts. You must submit an application and prove your expertise.

It's a guarantee for the people we want to work with, especially the architects and designers for whom we create fine cabinetmaking or unique pieces, especially abroad. It's proof of our expertise.

Don’t hesitate to consult our latest article: Lyon Beton, concrete at the service of decoration .

0 comments